Core Support Replacement (CSR) is a critical process in crashworthiness testing, ensuring vehicles' structural integrity during collisions. By focusing on key components like chassis, frame, and suspension, CSR enhances overall safety, facilitates bumper repair, and enables comprehensive vehicle restoration. Effective CSR prevents excessive deformation, maintains passenger compartment integrity, and reduces intrusion risks, thereby minimizing forces transferred to the cabin and improving occupant safety. Future developments in CSR include innovative materials and designs that integrate advanced safety features while reducing fuel consumption.

In the realm of automotive safety, core support replacement is a game-changer in crashworthiness testing. This critical process involves the strategic removal and substitution of structural components, aiming to enhance vehicle stability during collisions. Understanding core support replacement is essential for ensuring optimal passenger protection. The article delves into the fundamentals of crashworthiness testing, highlights the compelling reasons behind replacing core supports, and explores best practices for effective implementation, offering insights into future safety considerations.

- Understanding Core Support Replacement: The Basics of Crashworthiness Testing

- Why Replace Core Supports? Uncovering the Key Benefits for Safety

- Implementing Effective Core Support Replacement: Best Practices and Future Considerations

Understanding Core Support Replacement: The Basics of Crashworthiness Testing

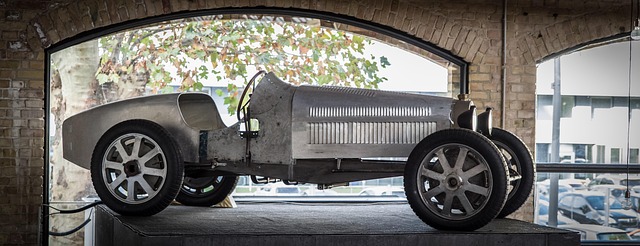

Core Support Replacement is a critical aspect of crashworthiness testing, focusing on the vehicle’s structural integrity during collisions. This process involves assessing and replacing or reinforcing key components, such as the chassis, frame, and suspension systems, to ensure they can withstand the forces exerted in various accident scenarios. Crashworthiness testing is a meticulous evaluation method designed to determine how well a vehicle protects its occupants and reduces the risk of severe injuries in the event of a collision.

It simulates real-world crash conditions, subjecting vehicles to controlled impacts at different angles and speeds. The goal is to identify weak points and vulnerabilities that might lead to structural failure. By implementing effective core support replacement strategies, manufacturers can enhance overall vehicle safety, leading to better bumper repair outcomes, improved tire services, and even the possibility of comprehensive vehicle restoration after accidents.

Why Replace Core Supports? Uncovering the Key Benefits for Safety

Replacing core supports is a critical step in enhancing the safety features of vehicles during crash situations. These components play a pivotal role in the overall structural integrity and crashworthiness of an automotive vehicle, especially during frontal or rear impacts. When involved in a car collision repair, the state of these core supports can significantly impact the outcome for both the vehicle and its occupants.

By replacing worn-out or damaged core supports, automotive body shops can ensure several key benefits related to safety. Firstly, it reinforces the vehicle’s structure, preventing excessive deformation during an accident. This is crucial in maintaining the integrity of the passenger compartment, reducing the risk of intrusion and potential injuries to the occupants. Additionally, modern core support replacement methods often incorporate advanced materials and design strategies, offering improved energy absorption capabilities. Such enhancements contribute to better crash management, minimizing the force transferred to the cabin, and thus enhancing passenger safety in the event of an automotive repair or collision.

Implementing Effective Core Support Replacement: Best Practices and Future Considerations

Implementing effective core support replacement is paramount for ensuring the crashworthiness of vehicles during rigorous testing. It involves meticulous planning and adherence to best practices. First, selecting suitable replacement parts that mimic the original specifications is crucial. These components should be sourced from reputable manufacturers known for their quality and safety standards. Furthermore, proper preparation of the damaged area, including precise measurements and surface treatment (such as auto painting or car dent repair), guarantees a seamless integration of new core supports during car body restoration.

Future considerations extend beyond mere functionality. As technology advances, manufacturers are exploring innovative materials and designs for core support replacement. Lightweight alternatives, for instance, can enhance a vehicle’s overall crash performance while reducing fuel consumption. Additionally, the integration of advanced safety features, like sensors and impact-absorbing zones, is expected to shape future core support systems, making them not just effective but also intelligent in mitigating crash forces during auto painting and car body restoration processes.

Core support replacement is a vital aspect of crashworthiness testing, ensuring vehicle safety in the event of a collision. By replacing these critical components, engineers can significantly enhance structural integrity and passenger protection. The benefits are clear: improved energy absorption, better distribution of force, and reduced risk of intrusion into the passenger compartment. As technology advances, adopting best practices for core support replacement and staying updated with future considerations will be essential to continue raising safety standards in the automotive industry.