The digital revolution has dramatically improved core support replacement in autos, leveraging advanced software for precise measurements and real-time data. These tools, including CAD systems and integrated diagnostic software, enhance accuracy, reduce labor times, and promote cost-effectiveness. Strategic planning, cross-departmental collaboration, updated standard operating procedures (SOPs), employee training, safety protocols, and post-implementation checks ensure a seamless transition to new core support systems in manufacturing and automotive repair, from tire services to vehicle dent repair.

In today’s digital era, the process of core support replacement (CSR) has undergone a remarkable transformation. Technology plays a pivotal role in enhancing CSR accuracy, streamlining workflows, and reducing errors. This article delves into the digital evolution of CSR, exploring how advanced tools and systems improve outcomes. We discuss best practices to ensure seamless transitions, leveraging technology’s potential to revolutionize this critical process, ultimately strengthening core support systems.

- Core Support Replacement: The Digital Evolution

- Technology's Role in Enhancing Accuracy

- Best Practices for Seamless Transition

Core Support Replacement: The Digital Evolution

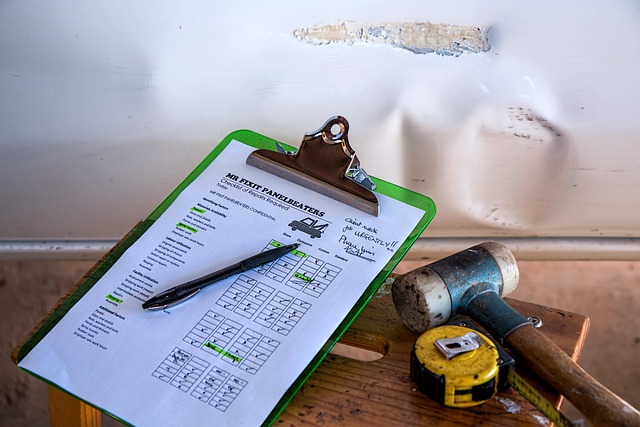

The evolution of digital technology has brought about significant advancements in core support replacement processes within the automotive industry. What was once a manual, time-consuming task relying on skilled technicians’ expertise is now streamlined through innovative tools and systems. Modern car repair shops leverage advanced software applications that provide precise measurements and real-time data, ensuring accurate replacements. These digital solutions offer step-by-step guides, virtual tutorials, and even augmented reality features, making complex procedures more accessible to mechanics.

This technological shift has revolutionized autobody repairs and vehicle repair services. With the help of specialized software, technicians can quickly access detailed vehicle models, identifying specific core support replacement parts and methods unique to each make and model. Digital evolution in core support replacement not only enhances accuracy but also improves efficiency, reducing labor times and potential errors often associated with traditional methods.

Technology's Role in Enhancing Accuracy

Technology plays a pivotal role in enhancing the accuracy of core support replacement processes in automotive workshops and collision centers. Advanced tools and software have been developed to streamline this critical aspect of vehicle repair, ensuring precision and efficiency. For instance, computer-aided design (CAD) systems enable technicians to plan and execute replacements with meticulous care, aligning parts perfectly for optimal performance. These digital solutions also reduce the margin of error by providing real-time data and visual aids.

Furthermore, integrated diagnostic software can accurately identify vehicle issues, including core support damage, by analyzing sensor data and on-board computer readings. This not only expedites the replacement process but also promotes cost-effectiveness by preventing unnecessary work on non-related components. With technology as an ally, collision repair services can offer more reliable and safer solutions, ensuring customer satisfaction and maintaining high standards in tire services and overall collision repair.

Best Practices for Seamless Transition

When transitioning to a new core support system, whether for manufacturing or automotive applications, best practices ensure a seamless shift that optimizes performance and minimizes disruptions. First, thorough planning is key. This involves assessing current processes, identifying gaps, and aligning objectives with the new technology. Engaging stakeholders from various departments helps in anticipating challenges and devising tailored solutions. Standard operating procedures (SOPs) should be updated to reflect the new system’s capabilities and limitations, ensuring every team member is well-informed.

Regular training sessions for employees can help bridge any knowledge gaps. Emphasizing safety protocols during installation and operation of the new core support system is critical. Leveraging existing resources and seeking guidance from industry experts or the technology provider can also aid in a smooth transition. Regular maintenance checks post-implementation are crucial to catch any anomalies early, thereby enhancing overall efficiency and reliability, whether for tire services, auto repair near me, or vehicle dent repair processes.

In conclusion, technology plays a pivotal role in enhancing the accuracy of core support replacement processes. By leveraging digital tools and innovative solutions, medical professionals can ensure more precise surgeries, reduced errors, and improved patient outcomes. Adopting best practices for seamless integration of these technologies is essential to stay ahead in the ever-evolving landscape of core support replacement.