Core Support Replacement (CSR), a specialized collision repair process, is crucial for vehicle safety and structural integrity while minimizing environmental impact. Eco-friendly practices like recycling parts and using sustainable materials are key, along with advanced paint repair techniques to reduce waste. The automotive industry is transitioning towards sustainability in CSR, focusing on material recycling, 3D printing, biodegradable composites, and digital design for lightweight construction. These innovations aim to reduce carbon footprints while enhancing efficiency and cost-effectiveness in vehicle repairs, balancing environmental stewardship with modern transportation demands.

“The environmental impact of core support replacement (CSR) is a growing area of concern within the industry. As essential infrastructure undergoes CSR, understanding its ecological footprint becomes paramount. This article explores the fundamental aspects of CSR and its environmental implications. We delve into key concerns such as waste management, material usage, and energy consumption, offering insights into current challenges and future sustainable trends shaping the CSR landscape. By examining these factors, we aim to highlight the importance of environmentally conscious practices in core support replacement.”

- Understanding Core Support Replacement: The Basics and Its Impact on the Environment

- Key Environmental Concerns in Core Support Replacement Process

- Sustainable Solutions and Future Trends in Core Support Replacement

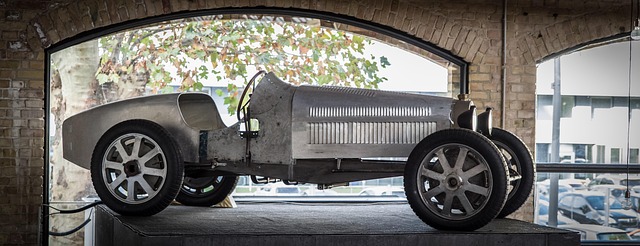

Understanding Core Support Replacement: The Basics and Its Impact on the Environment

Core Support Replacement is a critical process that involves the replacement of structural components within a vehicle’s body, often due to damage or wear. It’s a specialized repair technique aimed at restoring the car’s safety and structural integrity. This procedure demands precision and knowledge as it deals with the core elements that hold a vehicle together. By replacing these supports, collision repair specialists can ensure the car’s frame remains sturdy and safe for future use.

The environmental impact of core support replacement is an essential consideration. Traditional methods often involve intensive fabrication processes, leading to higher material waste. However, eco-friendly practices are emerging, such as recycling old parts and using sustainable materials for new replacements. Moreover, efficient repair techniques, like vehicle paint repair and collision repair services, can minimize the overall environmental footprint by extending the lifespan of vehicles and reducing the need for frequent replacements. This approach not only conserves resources but also contributes to a greener automotive industry, focusing on responsible car bodywork practices.

Key Environmental Concerns in Core Support Replacement Process

The core support replacement process, while crucial for maintaining structural integrity in vehicles, comes with several environmental considerations that cannot be overlooked. One of the primary concerns is the management of hazardous materials and waste generated during the procedure. Auto body repair often involves working with toxic substances such as solvents, paints, and adhesives, which require proper disposal to prevent soil and water contamination.

Additionally, the auto body work process must adhere to strict regulations regarding energy consumption and greenhouse gas emissions. Core support replacement can significantly impact a vehicle’s overall efficiency, and the methods employed during repair directly contribute to the carbon footprint of the automotive industry. As such, focusing on sustainable practices in auto detailing becomes paramount, including using eco-friendly materials, optimizing energy use, and minimizing waste generation at every stage of the core support replacement lifecycle.

Sustainable Solutions and Future Trends in Core Support Replacement

As the automotive industry shifts towards sustainability, core support replacement is also evolving. Sustainable solutions are emerging, focusing on recycling and reusing materials to minimize waste. Advanced technologies like 3D printing are being explored for producing core supports, reducing the need for traditional manufacturing methods that often rely heavily on energy-intensive processes. These innovations not only benefit the environment but also enhance efficiency and cost-effectiveness in collision repair and car scratch repair scenarios within vehicle body shops.

Looking ahead, future trends in core support replacement suggest a move towards even more eco-friendly practices. The integration of biodegradable materials and bio-based composites could significantly reduce the carbon footprint associated with automotive manufacturing. Additionally, digital design and precision engineering will play a pivotal role in optimizing core supports for lightweight construction, further improving fuel efficiency and performance while adhering to stringent environmental standards. These developments underscore the industry’s commitment to balancing environmental stewardship with the demands of modern transportation.

The core support replacement process, while vital for infrastructure maintenance, presents environmental considerations that cannot be overlooked. As we’ve explored through this article, understanding the key environmental concerns and implementing sustainable solutions are essential steps towards minimizing the ecological impact of this critical operation. Looking ahead, embracing emerging technologies and adopting circular economy principles will play a pivotal role in shaping a greener future for core support replacement, ensuring both robust infrastructure and a healthier planet.