Core Support Replacement (CSR) is an auto repair process that reconstructs structural elements like frames and body panels to ensure safety and aesthetics after damage. It involves meticulous waste management, responsible disposal of materials, and adoption of energy-efficient practices and eco-friendly materials. Sustainable CSR methods use recycled supports, efficient waste management, and renewable energy sources to minimize environmental impact, appealing to environmentally conscious customers.

“In the realm of construction and infrastructure maintenance, core support replacement (CSR) plays a pivotal role. This process, while essential, can significantly impact the environment if not managed sustainably. This article delves into the intricate world of CSR, exploring its environmental considerations. We’ll uncover key impact areas, highlighting the potential ecological footprint left by these operations. Furthermore, sustainable practices will be discussed as a means to revolutionize CSR, ensuring a more harmonious relationship between construction and nature.”

- Understanding Core Support Replacement: An Overview

- Key Environmental Impact Areas in CSR Processes

- Sustainable Practices for Minimizing Ecological Footprint

Understanding Core Support Replacement: An Overview

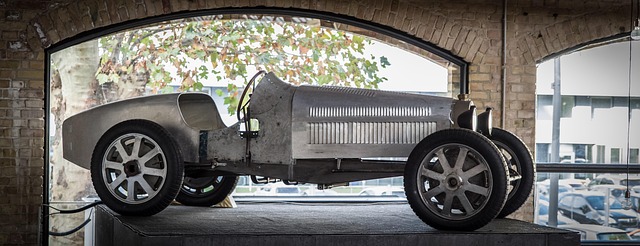

Core Support Replacement is a specialized process that involves the meticulous reconstruction and reinstatement of structural elements within a vehicle, primarily after significant damage, such as in collision damage repair or automotive restoration. This intricate procedure is crucial for restoring vehicles to their pre-incident condition, ensuring both safety and aesthetic appeal. It requires skilled technicians who can accurately assess and replace core components like frames, chassis, and body panels, which serve as the car’s backbone.

In an auto collision center, where vehicles undergo rigorous repairs, understanding core support replacement is paramount. It forms a pivotal aspect of the overall restoration process, addressing not just visible damage but also structural integrity. By focusing on these underlying components, technicians facilitate the seamless integration of various repair services, including body work, painting, and mechanical adjustments, ultimately transforming a damaged vehicle into a safe and visually appealing automotive masterpiece.

Key Environmental Impact Areas in CSR Processes

In core support replacement (CSR) processes, several key environmental impact areas require careful consideration. The first and foremost is waste management. CSR often involves the disposal or recycling of various materials, including old core components, auto glass repair debris, car dent repair byproducts, and even hazardous substances from specific parts. Implementing robust recycling programs and sustainable waste management strategies can significantly reduce the ecological footprint of these operations.

Additionally, energy consumption and greenhouse gas emissions are critical factors. The manufacturing, transportation, and installation of new core support systems can contribute to high energy demands and carbon emissions. To mitigate these impacts, CSR projects should focus on energy-efficient practices, such as using eco-friendly materials, optimizing production processes, and adopting renewable energy sources where possible. This approach aligns with the broader sustainability goals, ensuring that auto repair and replacement services not only maintain vehicle functionality but also contribute to a greener environment, much like how car paint repair techniques continuously evolve to meet environmental standards.

Sustainable Practices for Minimizing Ecological Footprint

In the realm of core support replacement, sustainable practices are increasingly vital to minimize a collision repair shop’s ecological footprint. By integrating eco-friendly techniques into automotive repair services, these shops can significantly reduce their environmental impact. One key strategy involves utilizing recycled and recyclable materials whenever possible, from parts to waste management. For instance, choosing recycled metal for core supports not only lessens the demand for new resources but also diminishes energy consumption associated with production.

Additionally, efficient waste management is another cornerstone of sustainable core support replacement. Auto repair services can implement measures like proper disposal of hazardous materials, recycling of non-hazardous waste, and even upcycling where feasible. These practices not only protect local ecosystems but also contribute to a greener image for the collision repair shop, appealing to environmentally conscious customers seeking high-quality automotive repair services.

In conclusion, understanding and implementing sustainable practices in core support replacement (CSR) processes is paramount to minimizing ecological footprints. By focusing on key environmental impact areas and adopting eco-friendly alternatives, industries can contribute to a greener future while ensuring the successful completion of CSR projects. As awareness grows, it’s essential to continue exploring innovative solutions that balance operational needs with environmental stewardship.