Core support replacement is a critical, precise process in equipment maintenance, ensuring longevity and optimal performance by skilled technicians using specialized tools. Post-repair quality assurance (QA) procedures are vital to maintain vehicle safety and customer satisfaction, including visual inspections and functional tests. Utilizing genuine or certified parts and regular maintenance extends the core support's lifespan, guaranteeing robust performance for years.

In today’s industrial landscape, efficient equipment maintenance is paramount for operational success. Core support replacement stands out as a critical step within this process, serving as a linchpin for extending machinery lifespan and ensuring optimal performance. This article delves into the intricacies of core support replacement and post-repair quality assurance, providing insights on implementing effective procedures to guarantee longevity and peak efficiency. By understanding these practices, businesses can navigate maintenance challenges and stay ahead in their respective industries.

- Understanding Core Support Replacement: A Essential Step in Equipment Maintenance

- Implementing Effective Post-Repair Quality Assurance Procedures

- Ensuring Longevity and Performance After Core Support Replacement

Understanding Core Support Replacement: A Essential Step in Equipment Maintenance

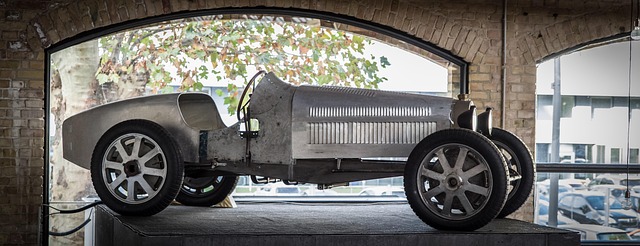

Core support replacement is a critical process that forms an integral part of comprehensive equipment maintenance routines. This essential step involves the careful removal and replacement of core structural components within machinery or vehicles, ensuring their longevity and optimal performance. It’s not just about fixing broken parts; it’s about restoring the integrity of the entire system, much like vehicle body repair or auto painting revitalizes a car’s exterior.

The process demands meticulous precision and a deep understanding of the equipment’s inner workings. Skilled technicians employ specialized tools and techniques to disassemble, inspect, and replace core supports, addressing potential weaknesses or damage that could compromise stability or safety. This proactive approach to maintenance not only prevents costly breakdowns but also enhances the overall quality of vehicle restoration or equipment repair, ensuring they operate at peak efficiency for extended periods.

Implementing Effective Post-Repair Quality Assurance Procedures

After a core support replacement, establishing robust post-repair quality assurance (QA) procedures is paramount to ensure optimal vehicle performance and safety. These processes serve as a bridge between repair and customer satisfaction, aiming to identify and rectify any potential issues before the vehicle leaves the collision center. Effective QA involves comprehensive inspections, including visual examinations of the replaced core support for proper alignment, fit, and integrity.

Additionally, functional tests are crucial to verify that all related systems—such as suspension and steering—operate seamlessly after auto glass repair or collision center treatments. By integrating these meticulous QA measures, the process ensures that vehicles meet the highest standards of quality and safety, giving owners peace of mind on the road.

Ensuring Longevity and Performance After Core Support Replacement

After successfully replacing a core support, the focus shifts to ensuring the longevity and optimal performance of the component in the restored car. This involves rigorous quality assurance checks that mirror those conducted during the initial manufacturing process. Every detail, from structural integrity to paint finish and panel alignment, must meet the highest standards.

A key aspect is using genuine or certified replacement parts that are designed to withstand the rigors of everyday driving and any potential future repairs, akin to how meticulous auto collision centers handle car body restoration and dent repair. Regular maintenance and inspections further safeguard against premature failure, ensuring the core support continues to provide robust support for years to come.

Core support replacement is a vital aspect of equipment maintenance, ensuring longevity and optimal performance. By implementing effective post-repair quality assurance procedures, professionals can guarantee that each step of the process meets the highest standards. This comprehensive approach, focusing on both the replacement itself and subsequent quality control, serves as a robust strategy to maintain the efficiency and reliability of critical machinery in various industries.