Core Support Replacement (CSR) is a critical automotive repair process that reinstates structural integrity in vehicle frames and bodies, addressing deep-seated issues caused by accidents or wear and tear. For Mercedes Benz vehicles, skilled technicians perform frame straightening to realign warped frames and subsequently apply car paint services for enhanced aesthetics and protection. An Environmental Impact Assessment (EIA) is a crucial step, guiding teams towards eco-friendly practices by analyzing air quality, water usage, waste generation, and local ecosystems. CSR utilizes recycled materials and innovative manufacturing techniques to minimize environmental impact while extending vehicle lifespans, aligning with sustainability goals and promoting harmony between human activities and planetary health.

In the realm of construction and infrastructure, Core Support Replacement (CSR) is a critical process that demands careful environmental consideration. As structures age, the need for CSR arises, presenting both challenges and opportunities for sustainable development. This article explores the fundamental aspects of CSR, with a particular focus on Environmental Impact Assessment—a vital component often overlooked yet crucial to shaping a greener future. Uncovering sustainable solutions, we aim to guide professionals in navigating the challenges of CSR while minimising ecological footprints.

- Understanding Core Support Replacement: The Basics

- Environmental Impact Assessment: A Key Component

- Sustainable Solutions for a Greener Future

Understanding Core Support Replacement: The Basics

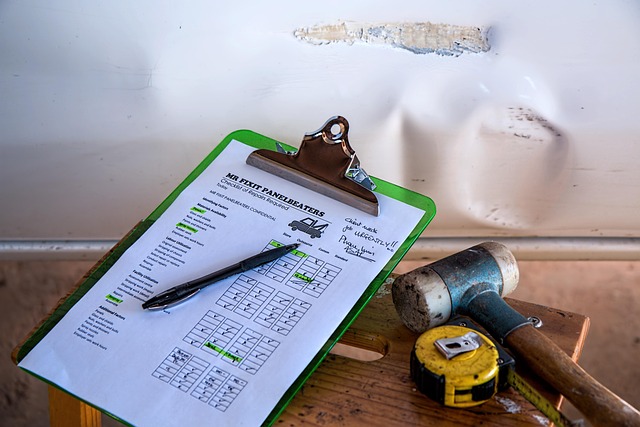

Core Support Replacement is a critical process in automotive repairs, focusing on the structural integrity of a vehicle. It involves replacing damaged or deteriorated components within a car’s frame and body, ensuring safety and longevity. This procedure is not merely about fixing visible dents or scratches; it delves into the core structure to address issues that might compromise the vehicle’s stability. For instance, in cases of severe accidents or long-term wear and tear, certain sections of the chassis and body may need to be completely overhauled or replaced.

In the context of Mercedes Benz repair, frame straightening is a key aspect of core support replacement. It requires skilled technicians to realign warped frames back to their original specifications. This meticulous process ensures that the car’s body remains structurally sound after the replacement. Moreover, car paint services often follow this critical step to restore not just the aesthetics but also the protective coating over the newly reinforced frame and body components.

Environmental Impact Assessment: A Key Component

Environmental Impact Assessment plays a pivotal role in any core support replacement project, ensuring that the process is conducted responsibly and sustainably. This comprehensive evaluation goes beyond merely identifying potential risks; it involves scrutinizing every aspect of the operation to minimize ecological footprints. By assessing factors like air quality, water usage, waste generation, and the impact on local flora and fauna, environmental experts can guide auto detailing and automotive repair teams towards more eco-friendly practices during core support replacement procedures.

A thorough Environmental Impact Assessment is crucial for implementing effective mitigation strategies. It enables professionals in the field of core support replacement to balance the needs of restoration with the preservation of the surrounding environment. Moreover, it aligns these projects with broader sustainability goals, ensuring that auto dent repair and similar endeavors contribute positively to the local ecosystem, rather than posing a threat to it.

Sustainable Solutions for a Greener Future

In the pursuit of a greener future, sustainable solutions are increasingly becoming paramount, especially within the automotive industry. Core support replacement offers an avenue to achieve this by minimizing environmental impact. Eco-friendly materials and processes can be employed during the replacement process, such as using recycled metal and innovative manufacturing techniques that reduce energy consumption. These measures not only contribute to a cleaner environment but also extend the lifespan of vehicles, thereby decreasing the demand for frequent core support replacements.

By adopting sustainable practices in car bodywork services, including efficient dent removal and repair methods, the industry can significantly reduce its carbon footprint. Vehicle bodywork repairs provide an opportunity to reuse and recycle materials, further mitigating environmental degradation. Embracing these green initiatives ensures that core support replacement becomes not just a technical procedure but a step towards a more harmonious relationship between humans and the planet.

In conclusion, core support replacement is not just a technical process but one that significantly impacts our environment. As we move forward, it’s imperative to integrate sustainable practices into core support replacement strategies. By conducting thorough environmental impact assessments and exploring eco-friendly solutions, we can ensure a greener future while effectively replacing core supports. This holistic approach will contribute to a more environmentally conscious construction industry.